In today’s era of rapid urbanization and rising pollution levels, air quality has become a significant public health concern. Whether it’s for personal health, industrial compliance, smart cities, or environmental research, accurate air quality data is essential. And at the core of this accuracy lies a critical but often overlooked process: sensor calibration.

This blog dives deep into what sensor calibration is, why it’s necessary, and how it significantly impacts air quality monitoring systems.

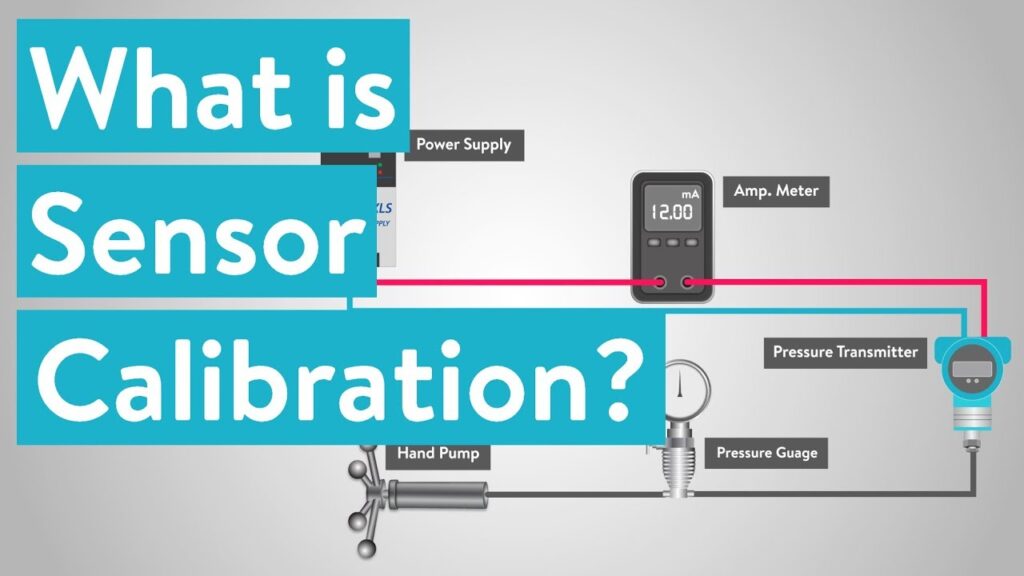

What is Sensor Calibration?

Sensor calibration is the process of adjusting and fine-tuning a sensor’s output so that it matches a known and accurate reference or standard. Every sensor in an air quality monitoring system is designed to detect specific air pollutants like particulate matter (PM2.5, PM10), gases like carbon dioxide (CO₂), nitrogen dioxide (NO₂), volatile organic compounds (VOCs), ozone (O₃), and more.

However, these sensors don’t always output precise measurements by default. Over time, due to aging, environmental changes, or component wear and tear, their readings can drift. Calibration helps realign their measurements with certified reference instruments or known standard values, ensuring continued accuracy.

Types of Sensor Calibration in Air Quality Monitoring

- Factory Calibration

- Field Calibration

- Auto calibration

- Cross Calibration

1. Factory Calibration

The sensor manufacturer performs factory calibration before the product is shipped to the customer. The sensors are tested under controlled lab conditions using certified reference gases or particles. This process sets a baseline performance standard for the sensor.

Pros:

- Ensures the sensor is accurate when delivered

- Ideal for plug-and-play use

Limitations:

- May not account for real-world conditions like extreme humidity, temperature variations, or local pollutants

- Calibration can degrade over time during actual use

2. Field Calibration

Field calibration is done after deployment, in the actual environment where the sensor operates. It involves comparing the sensor’s data with that from a high-accuracy reference monitor co-located in the same setting.

Why it’s important:

- Real-world factors such as temperature, humidity, altitude, and local air composition can affect sensor performance

- Field calibration adjusts for these variables, making the readings more reliable in the actual usage location

3. Automatic or Software-Based Calibration

Modern IoT air quality monitors sometimes come with self-calibration capabilities. These devices use machine learning algorithms or cloud-based reference datasets to recalibrate themselves over time.

Advantages:

- Reduces manual calibration effort

- Ensures ongoing accuracy in dynamic environments

- Ideal for scalable sensor networks

Caveat:

- Requires robust backend systems and well-trained models to work reliably

4. Cross-Sensor Calibration

This involves calibrating lower-cost or less sensitive sensors against a highly accurate, co-located reference-grade monitor within a sensor network. It’s widely used in smart cities, environmental research, or community air quality initiatives.

Use case:

- When deploying hundreds of affordable monitors, cross-calibrating with one high-quality reference unit brings consistency across the network

Why is Sensor Calibration Important for Air Quality Monitors?

Here’s a detailed breakdown of why calibration is not just helpful, but essential.

1. Ensures Accurate Data

Without proper calibration, sensors can display highly misleading readings. For example, a low-cost PM2.5 sensor could register an air quality index (AQI) of 50 (which is considered “Good”) when the actual level is 150 (“Unhealthy”).

Consequences of inaccurate data:

- People may unknowingly expose themselves to harmful air.

- Businesses may take unnecessary or ineffective mitigation actions.

- Scientific research using such data could be flawed.

Accurate data builds confidence in the system and allows for informed decision-making.

2. Builds Trust and Regulatory Compliance

In many industries and smart cities, air quality monitoring is part of regulatory compliance. Government bodies like the CPCB (India), the EPA (US), or the WHO have established air quality standards.

Calibration ensures:

- Compliance with legal standards

- Transparent and trustworthy reporting

- Accurate alerts during pollution spikes

- Data credibility for health advisories and policy changes

A non-calibrated monitor could lead to fines, public backlash, or failure in environmental audits.

3. Improves Long-Term Stability

All electronic components degrade over time. Factors like:

- Dust accumulation

- Temperature cycles

- Humidity exposure

- UV radiation

- Sensor aging

Can cause readings to deviate from actual values.

Periodic calibration:

- Corrects for sensor drift

- Maintains device reliability throughout its life cycle

- Helps avoid premature replacement of devices

It is essentially like routine servicing for your air quality monitoring system.

4. Crucial for Data Analytics and Smart Systems

Data from air quality monitors is often fed into:

- Air quality forecasting models

- HVAC automation systems

- Pollution heatmaps

- AI-driven insights for environmental planning

These applications depend heavily on the quality of input data. If the sensors are uncalibrated, it leads to:

- Inaccurate predictions

- Poor automated decisions (like unnecessary HVAC activation)

- Misleading visualizations or alerts

Sensor calibration guarantees that all derived analytics are based on truth, not noise.

5. Enables Standardization Across Networks

Let’s say a city deploys 100 air quality sensors. Without calibration:

- Sensor A might read 60 AQI while Sensor B reads 100 in the same air conditions.

- This creates confusion and destroys the integrity of the entire network.

Calibration ensures that all sensors in a distributed network speak the same language. This uniformity is essential for comparing, averaging, and responding to pollution levels across different zones.

How is Sensor Calibration Done?

Step 1: Baseline Measurement

The sensor is placed in a controlled environment or exposed to air with a known pollutant concentration.

Example:

- For PM sensors: exposed to air with 100 µg/m³ of PM2.5.

- For CO₂: use a chamber with exactly 1000 ppm.

Step 2: Compare with Reference

Simultaneously, a reference-grade instrument (like BAM, FEM, or chemiluminescence analyzers) also measures the same air.

Step 3: Adjust Sensor Output

The readings from the sensor are adjusted (via firmware or software) so they align with the reference instrument. This may involve:

- Applying correction factors

- Tuning sensor coefficients

- Using machine learning regression models

Step 4: Validation

Post-adjustment, the sensor is tested again to confirm that:

- Readings now fall within accepted error margins (usually ±5% to ±10%)

- The device consistently reproduces accurate results

What Happens If You Don’t Calibrate?

Here’s a table summarizing potential risks:

| Problem | Consequence |

|---|---|

| Sensor Drift | Incorrect AQI levels |

| Over-Reporting | Panic or unnecessary action |

| Under-Reporting | Exposure to health risks |

| Regulation Violation | Fines or loss of trust |

| Data Inconsistency | Useless for analytics or comparisons |

Uncalibrated sensors are like compasses that point in the wrong direction—they may look fine, but they take you nowhere useful.

Real-World Example: Airatom smart solution Monitors

At Airatom smart solution , we prioritize calibration at every stage:

- Factory Calibration: All sensors undergo multi-point calibration before shipment.

- Environmental Compensation: We apply algorithms to adjust readings based on the parameters.

- Field Calibration: Our clients receive regular support for onsite calibration, ensuring performance in real-world scenarios.

This makes our devices trusted by:

- Government agencies

- Schools and hospitals

- Researchers and data scientists

- Smart city deployments